From July 3 to July 26, 2018, Ju County Xinhui New Energy Co., Ltd. cleaned evaporative condensers with six sets of equipment, including four evaporative condensers with carbon dioxide refining and two evaporative condensers with compression process.

The condenser has not added any anti-scale and anticorrosive agent in the past year, and now the galvanized pipe has accumulated a thickness of 3 mm on the outer wall of the scale layer, which makes it difficult to clean and consumes a large amount of reagents. The most difficult part of this cleaning is to remove most of the dirt while protecting most galvanized coatings from corrosion.

After on-the-spot investigation, it was decided to add clay peeling agent to remove surface soft dirt and mucilage organic matter and colloid, then physical removal and cleaning pool work were carried out with high pressure water gun, and new water was replaced with cleaning agent at the end of cleaning pool work. The corrosion inhibitor, osmotic agent and medicament are cleaned, and then physical cleaning is done with high pressure water gun after cleaning, which ensures most of the galvanized coating is intact.

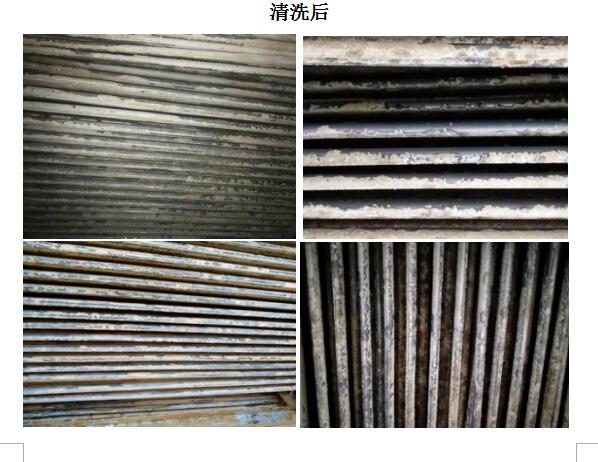

After cleaning, more than 80% of the scale is removed, and most of the galvanized coating is retained. The cross-comparison before and after cleaning is as follows: